Durham, North Carolina —Vulcan Elements announced the close of a $65 million Series A, led by Altimeter Capital and with significant participation from One Investment Management. This investment will accelerate Vulcan’s expansion to commercial scale to meet rapidly growing market demand—a critical milestone toward fully on-shoring the rare earth magnet supply chain and enabling the United States and its allies to dominate the 21st century.

Altimeter Capital, a premier technology investment firm with over $12 billion in assets under management, led the round. Known for backing category-defining companies, Altimeter believes Vulcan will “anchor the next century of American innovation and national security,” said Altimeter Founder and CEO Brad Gerstner. “Vulcan’s relentless execution has put it at the forefront of the industry. Vulcan has already emerged as a best-in-class manufacturer within two years of incorporation. There’s no one else in the rare earth space moving at this pace and with this level of performance.”

The round also included significant participation from One Investment Management—a global alternative investment firm founded by Rajeev Misra, former CEO of SoftBank’s $100 billion Vision Fund, who has helped build some of the most consequential businesses of the past decade—including NVIDIA, Uber, and Grab. With over $7 billion of assets under management, OneIM has deep cross-sector assets and expertise. “It’s rare to see a company in this space move with this level of speed, technical rigor, and focus,” Misra explained. “The importance of the magnet supply chain is more vivid than ever, and Vulcan is on track to be a cornerstone company for global manufacturing and innovation.” Misra and OneIM’s decades of experience in scaling industrial and commercial projects are distinct advantages for Vulcan as it expands.

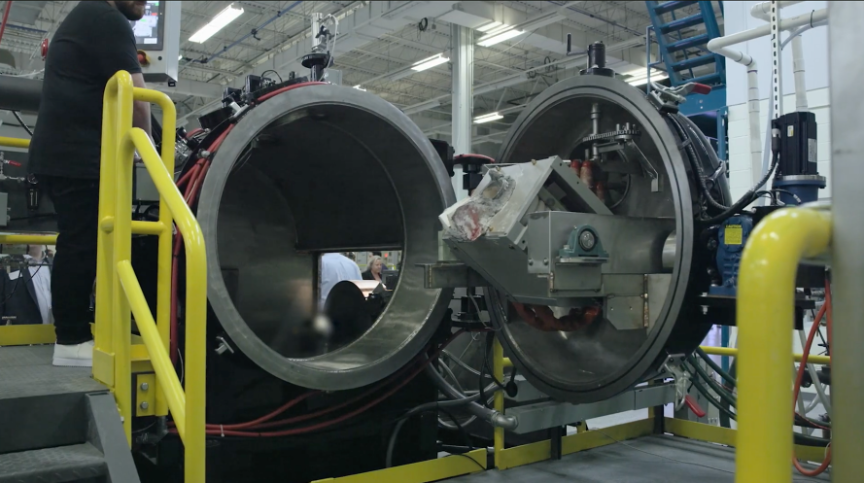

Vulcan is now producing high-performance magnets at its manufacturing facility in North Carolina’s Research Triangle Park. Vulcan’s magnets meet requirements across advanced defense and commercial applications—from drones and semiconductor fabrication equipment to hard disk drives, robotics, and automotive applications.

In the months ahead, Vulcan will supply magnets for every branch of the U.S. military, as well as leading American and allied technology companies. Chris Miller—author of The New York Times bestseller Chip War: The Fight for the World’s Most Critical Technology—described Vulcan as a “cutting-edge magnet manufacturer that’s advancing the entire magnetics industry and will accelerate American competitiveness in the technologies that will define the 21st century.”

Vulcan’s production process is decoupled from China. All of Vulcan’s material and equipment is sourced from the United States and its allies, ensuring complete traceability and transparency and providing customers the highest standard of security and resilience.

With its Series A funding, Vulcan will begin to scale to several hundred metric tonnes of annual magnet production in the next few years and several thousand tonnes by the end of this decade. “This Series A enables Vulcan to scale with the speed and seriousness that this moment and the nation demand,” said Vulcan Elements CEO John Maslin. “With Altimeter, OneIM, and others, we’ve brought together investors who understand what it takes to build enduring American industrial champions. Their support affirms what Vulcan has believed from the beginning: if we execute with discipline, we can rebuild one of the most critical supply chains of the 21st century—on U.S. soil.”

Vulcan isn’t just an alternative to China; it’s setting a new standard in magnetics science and innovation. Across its manufacturing process, Vulcan leverages novel technologies to accelerate production and reduce cost. Vulcan worked with the Department of Energy’s Ames National Laboratory to evaluate the properties and performance of our new magnet chemistry and process. Vulcan’s production process benefited from support from the Department of Defense—including contracts across the Air Force, Army, and Navy. Vulcan’s Chief Technology Officer, Dr. Piotr Kulik, opened the first rare earth magnetics lab in the United States in two decades, where he continues research to improve magnetic performance while training the next generation of magnetics experts.

Maslin describes rare earth magnets as “essential invisible building blocks of our economy.” Rare earth magnets are the strongest magnets in the world. They convert electricity into motion, making them essential to nearly every advanced technology and economic sector—from AI data centers and semiconductor fabrication plants to drones, robotics, satellites, and virtually all military platforms.

“This supply chain is China’s most painful chokehold over the U.S. economy and American national security,” Maslin added. China currently manufactures over 90 % of the global supply, while the United States makes less than 1%—leaving the United States vulnerable to having its economy frozen and its military production lines shut off by a Chinese export ban. “China has already weaponized its dominance of the magnet supply chain, most notably by cutting off magnet exports in April. That’s unacceptable,” Maslin affirmed, “and Vulcan Elements is bringing this supply chain back home.”

As it expands, Vulcan is focused on recruiting top talent from across the country. Engineers and technicians are the backbone of the company and essential to its mission. Candidates with experience in powder metallurgy, magnetics, advanced manufacturing, and scaling commercial operations are strongly encouraged to apply to join Vulcan’s growing team. Openings are posted on Vulcan’s website: https://job-boards.greenhouse.io/vulcanelements.

Vulcan Elements manufactures permanent sintered neodymium iron boron magnets in the United States for critical defense and commercial applications. The company remains committed to advancing technological innovations, galvanizing America’s manufacturing workforce, and collaborating with both public and private sector stakeholders to strengthen the domestic rare earth magnet supply chain.

Follow Vulcan’s journey on LinkedIn:

Vulcan Elements – linkedin.com/company/vulcan-elements

John Maslin – linkedin.com/in/johnmaslin

And on X:

For further inquiries, please contact:

Jonah Glick‑Unterman

Chief of Staff

Email: [email protected]